Work doesn’t stop just because temperatures drop. But bitter cold, snow and ice can wreak havoc on your aerial work platforms. Here’s a look at what you need to know to protect your machines during the coldest months…

Don’t leave your machines out in the cold!

It is recommended to store your machines indoors if you have the space.

Winter weather can cause a lot of damage to the exterior of your equipment, such as rust or paint chipping. By storing your machines in a temperature-controlled space, you will also better protect the engine and hydraulic hoses, which don’t fare well with fluctuating temperatures.

Remember to remove any attachments to minimize stress on joints and hinges if you plan to winterize your machine for a long time.

Inspect your tires

Tires are subject to severe damage when there are frigid temperatures outside. Solid tires are more prone to cracking in winter.

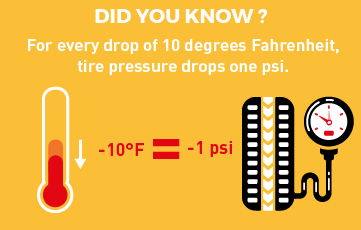

If your machine is equipped with air tires, we recommend that you check the tire pressure regularly. Under-inflated tires reduce fuel efficiency. They are also a safety hazard, as they can cause blowouts. In both cases, freezing outdoor temperatures can cause uneven tire wear, which can impact alignment, steering and traction.

To ensure your tires are in great working condition, carefully examine each tire daily!

Make sure moisture isn’t building up

Fuel problems increase in the winter.

Keep the tank full to avoid fuel injection system failure or fuel filter clogging.

Check fuel caps for leaks and don’t hesitate to add an additive treatment to the fuel to thaw filters, liquefy the fuel and remove condensation.

Check fluids

Oil and coolant are the two main fluids affected by winter.

Check your engine fluids and lubricants and replace them with winter-appropriate products. We recommend that you choose an oil viscosity that matches the outside temperatures so that you can work faster from a cold start.

Before winter begins, inspect the entire cooling system, including seals and hoses. Don’t forget to check transmission, brake and hydraulic fluids and components to ensure they remain in good working condition.

Use a cold weather package

Manufacturers such as Haulotte offer hostile environment packages to protect key components such as control boxes or boom sections from cold.

At Haulotte, the full hostile environment package includes upper and lower control box protections, cylinder bellows, booms wipers and turret ring wiper.

Take care of your batteries

Low temperatures are particularly hard on batteries. They drain their voltage, making it harder to start the engine. During the cold months, check the water level regularly and remember to periodically complete a full charging cycle.

Haulotte Activ’Energy Management is the ideal solution to extend the performance of the batteries. The smart charger respects all of the battery charging parameters and integrates many specific programs dedicated to battery maintenance so that your batteries last twice as long! You significantly reduce your maintenance costs and optimize the Total Cost of Ownership of your machines.

Increase your vigilance while in operation

As anyone who has ever run a lifting equipment in winter can attest, it’s no fun. Operation in cold temperatures and bad weather condition requires an even greater level of caution than normal.

Make sure aerial equipment has warmed up before starting work.

Take your time to move the machine to avoid collisions, breakdowns or accidents. Hidden patches of ice or frozen ground can cause equipment to slip! An area of snow can hide an obstacle or a frozen body of water…

When cold strikes, it is important for construction sites to stay active and productive. We strongly recommend you carry out regular and thorough inspections to keep aerial lifts running through the winter.