The circular economy: a new business model? Based on the eco-design of products, their repairability and recycling, circularity offers new perspectives in a period constrained by decarbonization objectives and rising raw material prices.

Grégory Richa, director of OPEO, a consulting firm specialized in industrial changes and transformations, and co-author of « Pivoting towards a circular industry », explains the benefits of circularity. Through his testimony, he gives us the keys to lead a company towards this model.

How would you define the circular economy?

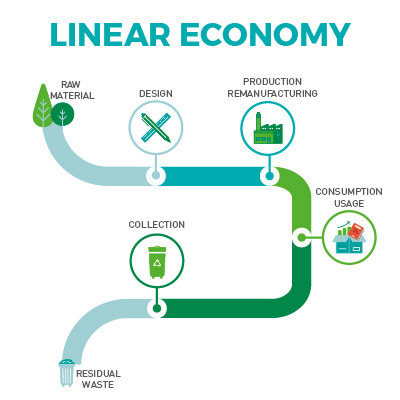

Today, we are in a so-called linear economy: it consists of extracting raw materials, manufacturing a product, and then throwing it away. This economy generates objects with a short lifespan while it takes decades or even centuries for waste to decompose.

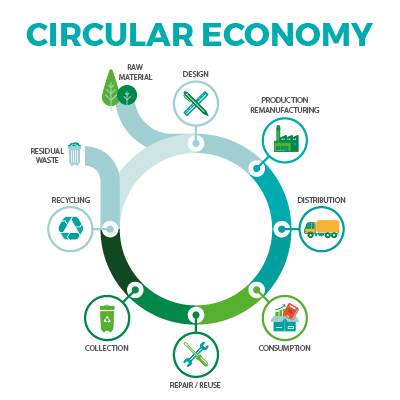

The circular economy will consist of expanding the lifespan of products and components, all while reducing the quantities of raw materials used and promoting the use of recycled materials. Today, only 7.2% of the global economy is circular. We are consuming more and more resources only to throw away more than 90% of this production.

This circular model is quite old. Why was it abandoned?

The circular economy disappeared with the rise of consumer culture in the 1960s thanks to mass production. To reduce cost and increase profits, these products were manufactured in countries with low labor costs. This moved us from a local economy to a global economy. With low-cost components, the reliability of products decreased along with their lifespan.

Eventually, economic models moved towards planned obsolescence and an increase in product complexity, the objective being to regularly renew product lines in order to generate more sales. A typical example is our smartphones. All these factors are leading to more and more waste because these products have become complex, inaccessible, and impossible to repair. Ironically, technological progress has led, and still leads, to a loss of circularity and product reparability.

The circular economy has been experiencing a resurgence of interest since the Covid crisis. Why?

The lockdowns in 2020, the blocking of the Suez Canal in 2021, and then the war in Ukraine in February 2022 have brought the global economy to a standstill. The price of raw materials has skyrocketed, and all supply chains have been affected by supply and transport problems. These events have highlighted the limits of globalization.

Manufacturers were also confronted with longer lead times to market new products, which in turn increased the value of the second-hand market. We started to use our equipment longer as well as recondition them, repair them, and put them back into circulation, which also generates income. This model was right in front of us, but these crises have made it essential. The other driver is the growth of electrification to move towards decarbonization. This is going to put a lot of pressure on materials such as steel and copper, which are at the heart of the electrification of most of our everyday products as well as the energy transition.

What are the main reasons for switching to this model?

The first question to ask is « Why are we doing it? Do we have a deep enough reason to go circular? » If so, switching to circular models can greatly unleash innovation and go so far as to transform the company’s mission by truly integrating environmental issues. Then you have to ask yourself if the product has potential for circularity. If everything in my device is sealed and none of the parts are accessible, it will be difficult.

On the other hand, if the product has a strong potential for repairability, we can start moving towards circularity. The next question is the business model. We can create a new business model, launching a range of remanufactured or reconditioned spare parts for repairable products. These parts, which are cheaper than new ones, will enable us to address a new market. The last factor is the industrial model. Recovering products to refurbish and resell them requires a circular chain of operations. How do we organize the recovery of products, recycle them, know where to repair them? A new chain and a new organization must be created.

This shift in business model cannot happen overnight. How can a manufacturer make the leap?

Actually, companies hold all the cards. If an industrial company knows how to manufacture, it also knows how to repair, so industries have the technical capacity to enter the circular economy. If there are fewer sales tomorrow in the automotive industry, the assembly lines that are not used to make new products could be used to reassemble products that are being repaired, for example. For the operators, this avoids repetitive tasks. It creates a sense of purpose for the teams because it generates local employment and is environmentally friendly.

We must therefore identify the company’s internal strengths. Then, you have to mobilize your external strengths, listen to your market, go to your distributors and customers to understand the use of the product and its lifecycle. This allows you to determine which service to provide in the circular economy and to create a difference. After that, you have to test that service on one or two customers. A company can make this journey in 6 to 18 months. It can also be forced to do so, due to the shortage of raw materials and the obligation to decarbonize. All companies are going to have to move towards a circular economy within 5 or 10 years because of these external constraints.

Which companies have already made the choice to go circular?

I would give the example of Mob-Ion, a French industrial start-up that manufactures electric scooters specifically designed for sustainability, aimed at being rented to communities or companies. Their approach is not to sell scooters, but rather to propose a subscription offer with a maintenance service. Their scooters are designed so that each part has several life cycles and is repairable.

In terms of large companies, there is also the example of Saint-Gobain, which works on recycled flat glass by setting up circular channels. Almost 100% of flat glass waste, used for our windows among other things, is buried, even though this can be reused to make flat glass again and again. The potential for circularity is huge.

Renault Trucks has been offering remanufactured spare parts for a long time now. The manufacturer also offers ways to extend the life of existing trucks, improve their performance, and reduce their carbon footprint. The prevailing business model, which consists of selling a diesel truck with maintenance services, will become outdated with the technological breakthrough of electric trucks, which require far less maintenance. Products and services will evolve towards the economy of use without owning, retrofit, recycling of batteries or truck parts for re-use.

Can circularity also be introduced as early as the design process of the machine?

By putting used parts on the market, a company may think that it will no longer sell new parts. But in every market, there are customers who only buy new and not second-hand. However, if you don’t do second-hand, you will lose some business opportunities because someone else will. It’s not intuitive, but if you create a range of second-hand products, you open up new markets. An eco-designed product which is good for the planet, local made-in, repairable, and lasts longer can also sell for more money. You shouldn’t assume that it will be less profitable, rather the opposite. A circular economy allows you to find complementary markets and enhance the premium side of your product.

In summary, what benefits should we remember about the circular economy?

The first one is economic performance, even though this is counterintuitive. People think that circular economy, with its waste management for example, is a constraint. Instead, we need to see in this waste a wealth with which we will still create value. The second type of benefit is the positive externalities.

Circularity has a positive impact on the planet, its resources, and it boosts local employment. The last benefit is its significance. Circularity creates projects that will transform the company, enhance its teams, and develop its capacity for innovation.

RESTART by Haulotte

Haulotte has launched a program dedicated to circularity, the first manufacturer program dedicated to the reconditioning of used aerial work platforms in Europe.

Restart Center by Haulotte, launched in July 2022, this new business model confirms the Group’s commitment to a more sustainable development.

The RESTART program by Haulotte has been designed to meet the growing demand for reconditioned aerial work platforms from the Haulotte brand.

As Ludovic Jankov, Haulotte’s Used Equipment Manager, points out, « Our offering is positioned between the traditional second-hand market, where platforms are sold without warranty, and new equipment. This new model allows us to offer quality reconditioned equipment, available immediately at a reasonable price. At the same time, it helps reduce our environmental impact. »

The RESTART program has been designed to respond to changes in sustainable and efficient resource management and to provide solutions to customers who are concerned about these issues. To successfully carry out this ambitious project, Haulotte has converted its factory in L’Horme (France) into a reconditioning center for second-hand aerial work platforms.

After only 9 months in operation, it is obviously too early to draw any conclusions, but the Group has already noted its customers’ interest for this type of offering. Renters and end customers alike are also involved in these changes, and they must take part in them.

Grégory Richa (OPEO) co-authored with Emmanuelle Ledoux, General Director of the National Institute for the Circular Economy, « Pivoter vers une économie circulaire », published by Dunod in 2022.

This 124-page book is made up of interviews and surveys conducted among 60 industrial companies of all sizes that are experimenting with circularity. Both a source of reflection and a practical guide, this book gives the keys to succeed in this inevitable transition. « We cannot continue to throw away 90% of what we produce. The circular economy is a recent phenomenon. It’s been three years since companies really caught on to it. And it’s going to continue to grow enormously » Grégory Richa assured.