Baptiste Roland joined the Haulotte Group in 2015 as Marketing Product Manager. He is in charge of characterizing customer needs and adapting them in terms of product offer on all markets. Over the past few years in particular, he has followed up on the development of Activ’Energy Management, a new innovative system designed by Haulotte to improve the performance and life of batteries. We met with him to talk about it.

You have been working for several years on new devices for battery maintenance and optimization. Why this particular subject?

The cost of battery maintenance and replacement is a priority issue for all our customers. For equipment rental companies in particular, regardless of the markets they serve, the main item of maintenance cost on our range of electrical machines concerns batteries. A number of our customers replaces these batteries every one or two years, even though they are designed to last five to six years under optimal use and maintenance conditions. This extremely high range, from X5 to X6 in some cases, has convinced us to engage ourselves in research and development work to design new solutions.

In partnership with the French Alternative Energies and Atomic Energy Commission (CEA), Haulotte’s innovation department has been working for more than five years on an extensive analysis of used batteries and on the reasons for their anticipated deterioration.

What types of batteries are we talking about?

We have concentrated our analytical work on models of lead batteries with an electrolyte composed of sulfuric acid (which can be open or sealed). Today, it is the dominant technology on the market. They constitute 70% of the batteries produced and equip the majority of electric construction vehicles on the road worldwide. These are the batteries used to equip Haulotte electric machines, the ones that allow the best optimization of Total Cost of Ownership (TCO).

It is an affordable, stable, safe, recyclable technology with excellent potential in terms of autonomy, recharging, lifespan and maintenance, but they are fragile elements. The production of energy is based on a succession of chemical reactions. These batteries almost have an organic life pattern as they can easily deteriorate themselves under poor conditions of use and maintenance.

What are the reasons for this accelerated deterioration?

We have identified three main lines of work and optimization.

1. Storage conditions for batteries when they are not in use (under conditions and for periods that can vary greatly).

2. The optimization of battery charging.

3. The equalization of the water fill on these open lead-acid batteries, which is also very important.

And what are the solutions developed by Haulotte in this context?

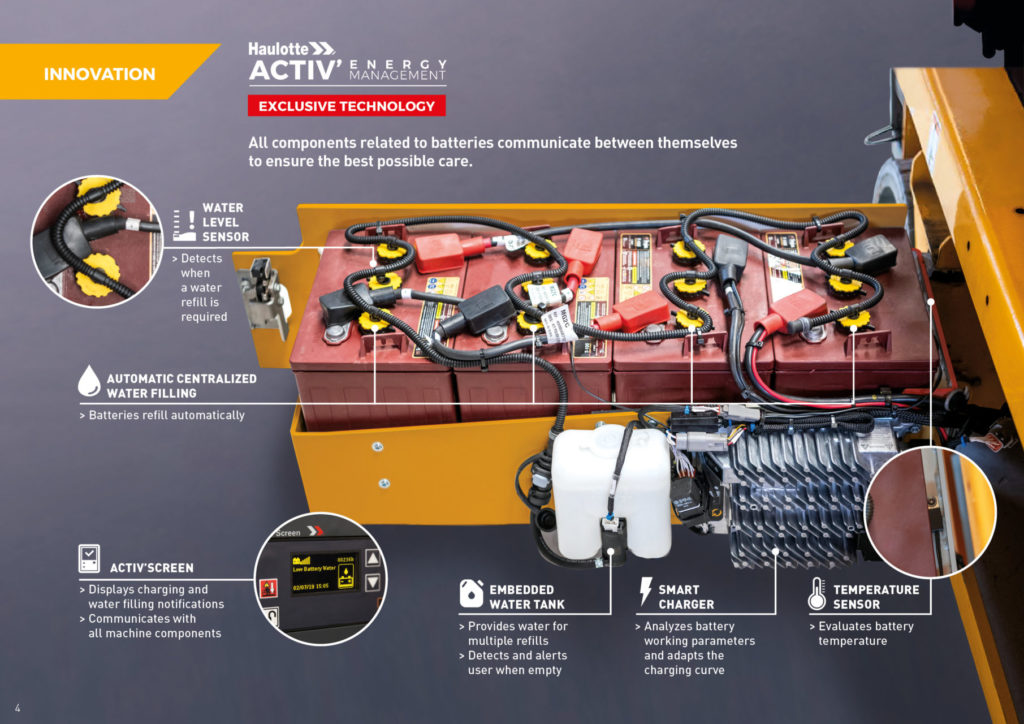

We have developed a global system that brings together various solutions called Activ’Energy Management. This exclusive technology combines an intelligent CAN charger (smartcharger) associated with centralized water filling solutions to make technicians’ daily life easier.

This smart charger offers different functions?

This new smart charger integrates on one hand the specificities in terms of power supply (taking into account the level and regularity of tension, voltage and ambient temperature) and on the other hand the different charging parameters (curves) of each battery. Via the control screen, the Haulotte smartcharger indicates to the operator when and how to charge the battery in order to avoid incomplete charges that quickly degrade the battery’s capacity.

It also incorporates equalization charging cycles dedicated to battery maintenance. These are periodic automatic charges (long) that rebalance the charge of each of the cells in the battery.

This smartcharger also has an optimized restart system to wake up batteries that have been switched off. Technicians often have the habit in this case of shocking the batteries with very high voltage for a short time. The Haulotte smartcharger delivers a low voltage for a longer period of time, making it possible to wake up any battery without damaging it.

Finally, we have equipped our smartcharger with a desulphation program. Over time, the various elements (electrodes, cathodes, etc.) become covered with sulfate, which reduces their efficiency. These regular desulphation programs give the battery a second lease of life without technical intervention.

What about water filling?

We offer a new centralized water filling system. It allows all cells to be optimally filled with water from a single container. This system is available in manual or automatic mode. In the latter case, it is simply necessary to keep the onboard water tank filled. There is nothing else to do.

In the end, all of these solutions developed by Haulotte make it possible to multiply battery life by up to 2 or 3, while drastically reducing the associated maintenance time and costs.