Falls are the leading cause of death in construction*. Although MEWPs offer a safe platform equipped with a guardrail, accidents can occur. All it takes is a slight impact with another machine, a collision with a building, or a bump in the road … To reduce risks when working at heights, it is recommended to equip yourself with fall arrest equipment. This article provides you tips to properly use a safety harness.

Do you need to wear a safety harness to operate a MEWP?

Regulations differ from country to country. Beyond the existing regulatory requirements, there are three other criteria to consider for wearing a harness:

- Aerial work platforms’ manufacturers can impose the wearing of PPE. The information must be clearly indicated in the user manual and an anchoring point must be provided.

- The client company may also require the use of a harness to protect against the risk of falling. In this case, the employer must provide his employees with all the necessary equipment.

- A job-specific risk assessment is essential to determine if you need to wear a safety harness. This assessment must be done before the work begins.

What are the different components of an anti-fall kit?

To work safely at heights, your fall arrest equipment should consist of a harness, an anchor point and a connection system.

The harness is a device designed to reduce falls’ accidents. It must be adapted to the task to be carried out as well as to the work environment. Choose a model that fits your size, preferably with wide, adjustable straps for maximum support and comfort. The ease of dressing and the position of the attachment point (ventral, dorsal, sternal, or lateral) are also determining factors. The dorsal attachment (located in the upper part of the back) is effective in preventing damage to your spine.

When working at height on a mobile elevating platform, it is recommended to adjust your lanyard as short as possible in the basket to restrain fall. The lanyard should be equipped with an energy absorption device to reduce the effects of the shock during the fall. At each end of the lanyard is a connector (one for the anchor point, and the second for the attachment point on the harness). Make sure the connectors are lockable, whether they are manual or automatic.

The anchor point is a vital element to secure your movements. Always attach your harness lanyard to the approved anchor point when entering the MEWP basket!

Checking your equipment

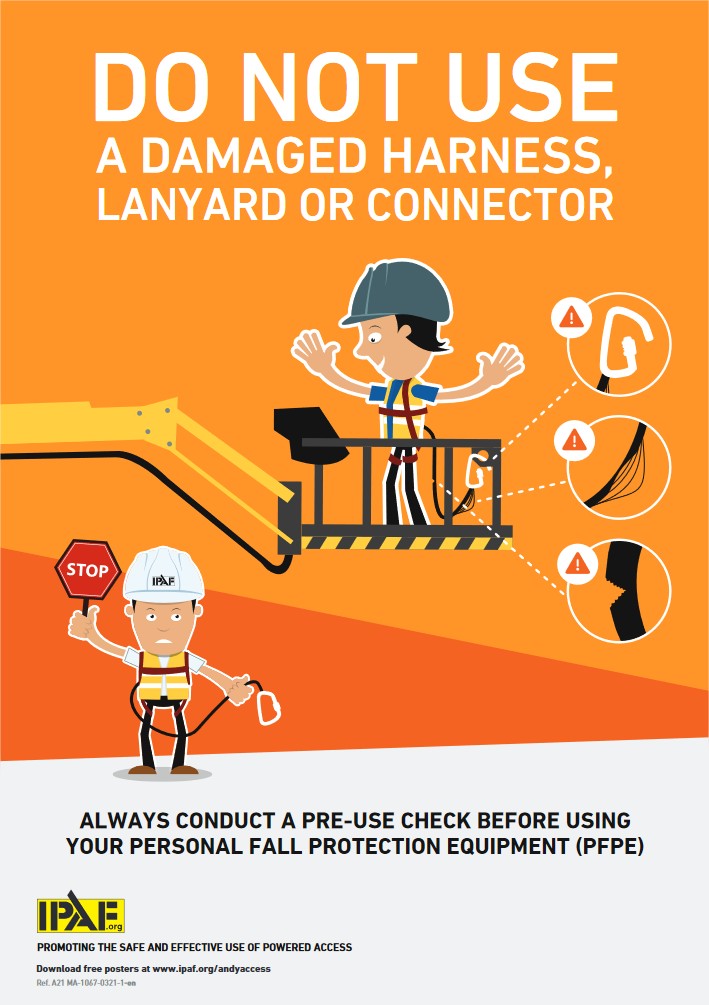

Through use, PPE (Personal Protective Equipment) can be damaged, worn or lose parts. All devices must be checked at least once a year by a controller of an accredited organization, or an employee trained in the verification of harnesses. In addition to these annual inspections, it is essential that you carry out a pre-use inspection of your fall arrest system. Here is a list (not exhaustive) of things to check:

- Make sure the harness has all the necessary information, such as serial number, manufacturer’s contact and inspection dates.

- Check the harness straps for cuts or chemical marks.

- Check for safety seam wear.

- Perform a tactile and visual check along the entire length of the rope of the lanyard (cuts, lint, hard points, soft or crushed areas…)

- Check the condition of the connecting buckles (marks, wear, cracks, deformation…)

- Check the correct operation of the locking/unlocking system.

If you believe your PPE is faulty, isolate it, tag and remove the equipment from service and report the fault to your employer.

Never use a harness, lanyard, or connector if there are signs of damage.