Transforma Robotics Ltd is a spin-off company from Nanyang Technological University (NTU), aiming to develop robots and robotic services to enable safe, cost-effective, and efficient construction. Founded in 2017 and based in Singapore. This company is committed to introducing new robotic technology to help companies address the labor shortage, increase productivity and improve workplace safety.

Co-founder and chairman of Transforma Robotics, Professor I-Ming Chen, of NTU’s School of Mechanical and Aerospace Engineering, agreed to give Haulotte an interview in which he told us about his company, their cooperation with Haulotte, and his vision of lifting equipment and robotics.

First of all, could you tell us more about yourself and Transforma Robotics and its activity?

I have been working in robotics for more than thirty years, and I am still a professor at the Nanyang University in Singapore. Until the beginning of this year, I used to be CEO of Transforma Robotics, a company I co-founded and of which I am still chairman. My primary role- and it was already the case in the past – is to set the R&D and product direction.

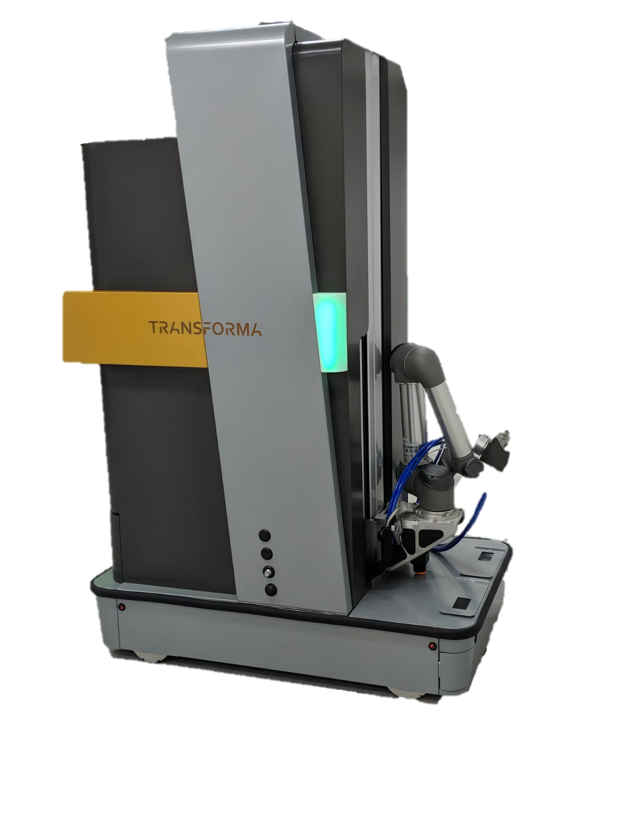

Since 2017, Transforma Robotics has been developing “construction robots”. Our current range consists of an autonomous spray-painting robot called PictoBot and a quality inspection and assessment robot called QuicaBot. We have also recently launched XDBot: a robot dedicated to disinfection in construction and other industries.

What type of customers are you working with? Could you provide a few names and concrete examples?

Our customers are main contractors, developers, and subcontractors. If we talk about our painting robot more specifically, we have many customers from the painting materials companies. I think it is linked with the industry: paint suppliers are not facing the end-consumers and performing painting jobs. They can manage these sales through their website, but they hire subcontractors to complete the actual work. In our case, the companies are looking for us because subcontractors may not have enough workers, especially with the COVID-19 standards and requirements. It is where our robots step in. They help and complement human workers, to alleviate their workload.

It is generally the type of clients we currently help. Most of them are in Singapore, but we work with several multinational companies that operate in Singapore and their respective home country. For example, we have an ongoing collaboration with Kajima Corporation, one of the oldest and largest construction companies in Japan. As part of this collaboration, we are working in Singapore and extending our activity to Japan and other countries, for their overseas works that require our robots. At the moment, we are mainly focusing on Singapore, but we are presented in other places through our different types of partners.

Transforma Robotics has decided to use Haulotte equipment for specific jobs and tasks. Could you please tell us more about that? What machines? What purpose? How does that work exactly?

We are using the Haulotte Star 10 vertical mast. We put it together with a robotic arm, and we integrate controls to make it a system for robots working at height. The robot can then go up to 8-10 meters high. As part of this process, we develop our intelligent spray painting method. We use perception and camera systems to help the robot paint automatically odd areas: surfaces that may have corners, beams, Etc. We use all this along with Haulotte modules for painting works at height.

We have chosen this specific model because of its compactness first and its useful ability to reach the heights we face in most jobs. I think we mainly use it for indoor jobs, but it can work for specific outdoor jobs as well. If other people and customers request even higher reaches, we could use other models from Haulotte range! The Star 10 is the only model we are using now and only with our Pictobot for painting and coating jobs. Should there be requests for jobs at height, we might robotize Star-10 to use together with your equipment!

You have chosen Haulotte vertical masts to make work at height more comfortable and for their compactness. But are there other reasons, such as reducing potential risks or gaining even more precision?

Safety is the first reason. With robots, we no longer have humans working at height. Then, you have workers’ health: in spraying jobs, there are chemicals, especially in protective coatings. Even when reducing spraying, you still need to wear protective gear. And third is productivity. Indeed, the robot does paint faster and more accurately, so we have improved overall quality. But I would like to emphasize that these are other considerations because when you put humans as a priority, the primary factors are most definitely safety and health. Then, you have productivity and quality.

Has the COVID pandemic been and still is critical in the decision to use Haulotte equipment? Or is it something that you wanted to experiment even before that?

COVID-19 for sure has affected people’s mindset and perception of automated equipment. I should actually say “change” rather than “affect.” Many workers currently cannot access work sites in Singapore and many other locations. To move things forward, you must resort to an automation or remote control system that allows the machinery to be operated safely in the most hazardous environments. In this context, using robotics enables the use of such equipment as an alternative. That being said, I believe that the COVID-19 crisis is just accelerating this trend that already existed.

Regarding the efficiency of Haulotte equipment, and to be truly honest, this project is still under development, which is why I am not able to give you in-depth data or figures. However, when you perform any work, let’s say painting, the current standard method would probably be to use the Haulotte platform and have two persons on top, carrying-out the actual work, and one safety officer at ground level. That is a total of three persons. You can replace the two persons on the equipment with robotic means and have only one on ground level, to oversee both the process and the equipment.

This person should have proper training related to this specific equipment and know-how to operate a robotic system. You can essentially have one person handling a task that required three in the past, not to mention that Haulotte equipment has an interface that allows a good integration! I suppose you want figures or statistics based on experience and calculations. In that case, the saving would be approximately 40% on the completion time and the same for paint used, not forgetting that the system only requires one person on-site.

How and when exactly did you come up with the idea of using lifting equipment for such a task? Why did you choose Haulotte rather than another company?

Following the company’s official creation in 2017, we figured out it was maybe not a viable solution to design our own elevated platform. Last year we decided to look for a suitable partner that could provide equipment in combination with our robots in jobs requiring to work at height. We already knew Haulotte via some of our partners who have used Haulotte machines and have very positive feedback on their reliability and performance. After several rounds of discussions with Haulotte Singapore General Manager Darren Phua, we decided to work with Haulotte. We have been delighted with the partnership and support provided by Haulotte Singapore so far.

Do you consider using other Haulotte machines in the future, like HA26 RTJ articulating booms, for example? Do you plan to use the same Haulotte equipment but with other robots?

We have not used this model yet. It is something we are just considering. We will see. Should we have jobs that require going even higher, we might indeed explore new options among your fleet of machines. The critical point is to meet the needs of our customers. If they need to go above 20 meters, we will consider the equipment that allows that. As for the second question, we are working on this, but it depends on the specifications. Such equipment can be designed and produced as a standard product, but we can make customizations when and if needed, for sure. It is a Win-Win for this partnership that is most important.

How would you define the robotics industry’s specificities, both in Singapore and worldwide?

Good question! It is something that varies a lot from one country to another. Here, robots are associated with manufacturing, a sector representing 20% of the GDP of Singapore. This includes manufacturing related to electronics, aerospace, pharmaceutical, and other fields. Moreover, we have started to see more and more robots used in the healthcare sector, like surgical robots. The service industry has also extended its use of robots, in restaurants for example.

The government is also pushing for construction robots and automation of processes, which we are developing now. It is critical because Singapore has a significant shortage of workers in construction. All these issues are related and interconnected. But this trend is also emerging on a global scale, not just in Singapore.

More specifically, what are the latest evolutions in robotics, and how do you see its expansion in the short and long term?

In my opinion, when it comes to robotics, the qualifying term we should use is indeed evolution rather than revolution, because this is a sector which has witnessed developments for more than fifty years and that has already known at least three cycles. We are getting close to a fourth peak that could last a very long time. Aging society is indeed a significant issue for most developed countries, and even for some developing countries, such as China, where the living standards are rising very fast. Therefore, we see this increasing use of robotics in more and more sectors: manufacturing, but also healthcare, and services, like I said earlier.

We could also mention autonomous driving. Activities in ports with autonomous vehicles are already in operation at some of the world’s most advanced ports, such as Singapore, with tests planned by rail and road using 5G networks beyond the yard gates. I believe we face a phenomenon that will accelerate and last very long. Another aspect, which is quite apparent in China, is all the robotic components that are becoming cheaper and thus more affordable for a growing number of persons and companies: sensors, cameras, etc. It makes the adoption and integration of robotic solutions more straightforward and faster.

If we focus again on the lifting sector, what could be the key factors to develop and expand the combined use of elevating equipment and robotics?

I am sure this type of combination will develop a lot in the future, both in quantity and variety. We will use this type of equipment to lift humans so they can work at height. But this will be gradually replaced with robots or another automated type of equipment. We want this to happen faster, so we need to consider the overall system reliability, safety, etc.

In terms of engineering, specifications and marketing, and communication, what would you expect from Haulotte to meet your demand and strengthen this partnership?

We see this partnership as a “co-creation process.” We have the robotic expertise, and you undeniably have the equipment knowledge and expertise. Working together can allow us to make such equipment more optimized, with even deeper integration of our robots’ interface. It is difficult to tell you more now because the COVID-19 pandemic is continuing. It does not prevent us from working, but it sure creates some constraints and restrictions. That being said, it is also an accelerating factor in using and accepting robotic systems, so it balances things out!

This partnership might indeed take time, even if I think we might see some results around the third quarter of 2021, but this is an exciting and promising project, in which I firmly believe!