Energy and power management is always a challenge on job sites for site and fleet managers. Anticipation is as key to success as having good habits for storage and recharging. These days telematics allows you to be more rigorous by monitoring and checking the battery system’s condition at all stages of your machine’s operation and battery charging.

No matter what type of Mobile Elevated Work Platform (MEWP) is on your jobsite, it’s essential to be confident in the capabilities and performance of the batteries. Therefore, knowing the load level of your machine battery pack and what can or can’t be achieved with it, can drastically improve the MEWP’s efficiency and performance.

Batteries are designed to be easy to charge and maintain, highly efficient and forgiving of misuse. It’s essential to understand how a battery works in order to provide correct care, good maintenance, and precise monitoring. Haulotte experts have identified three main causes of battery failure:

- Poor storage habits

- Inappropriate charging habits

- Lack of waterfilling

Extending the lifespan of batteries

The lifespan of a battery is difficult to predict, as it will vary application, frequency of usage and level of maintenance. The first and most simplest tip is to keep the battery performing at a high level of charge as long as possible.

According to our experts keeping the batteries over than 70% of SOC (state of charge) will drastically reduce sulfation and allow batteries to perform longer. Remember never store a MEWP with a battery deeply discharged, this could considerably reduce its performance and increase sulfation.

5 charging habits to implement:

1. Recharge after each day shift because unsuitable charging frequency and duration can deteriorate chemical components of the battery

2. Recharge before SOC drops below 20% to avoid deep discharging. Remember that a discharged battery creates harder sulfation

3. Once a week perform a full recharge of the battery and reach 100% of SOC (don’t stop before, not even at 98%)

4. Respect the recommended charging curve: the recharge must follow recommended battery charging curve unique to the brand and the battery model. The charging curve is defined by the manufacturer’s and depends on temperature: the hotter the temperature, the longer the charging time. To take full advantage of the curve, it is recommended to always use the manufacturer’s recommended chargers or the connections provided with the machine.

5. Every 7 full charges, charging should be extended to include an equalization phase. Equalization enables batteries to recharge back to the original level, increasing their performance. To equalize, simply leave the machine plugged in for 3 more hours after a full charge. Warning: equalizing charge should NEVER be done or AGM or GEL batteries.

Desulfate batteries: a necessary habit sometimes forgotten

Sulfation is the formation of lead sulfate compounds on the battery’s plates. Sulfates deteriorate battery performance. While stored, hard sulfation naturally occurs. Desulfation is the process that dissolves the sulfate layer and regenerates the battery using an ultra-slow charging mode (or electric negative pulse). It is advisable to perform a desulfation cycle every 6 months.

Good conditions of machine storage:

Store batteries only when fully charged and recharge it every month. Batteries gradually self-discharge during storage. Monitor the specific gravity or voltage every 4-6 weeks or do a full charge every month.

During storage, manage the ambient temperature: in the event of extreme temperature recharging must be more frequent.

When operating batteries at temperatures below 27°C (80°F) they will deliver less than rated capacity. For example, at -18°C (0°F) the battery will deliver 50% of its capacity and at 27°C (80°F) it will deliver 100% of its capacity. When operating batteries at temperatures above 27°C (80°F) they will deliver more than the rated capacity, but the battery life will be reduced.

Keep in mind that the discharge phenomenon will speed-up in hot weather. Avoid charging at temperatures above 49°C (120°F). Conversely, when it’s cold always let your MEWP plugged-in when it’s not in use. The best storage conditions are inside a building with stable and constant temperatures. To be noted: an increase of temperature about 10°C (50°F) divides the battery life by 2.

5 points

for successful storage

of your MEWP or batteries

- With the appropriate protective equipment and according to your country’s regulations, and required authorizations, disconnect the main power circuit plug

- Check for the absence of oxidation on the battery terminals

- Make sure cable terminals are tightly attached to the batteries

- Perform a complete charge

- Check water levels and if needed, fill to the recommended level with deionized or distilled water

When the machine or batteries are taken out of storage, connect the main power circuit plug and fully recharge before use.

Water: the battery's oxygen

Lead acid batteries contain a mixture of water and acid. During the charging process, water is lost. If electrolyte level drops below the tops of the plates, irreparable damage may occur. It is very important to inspect the water level twice a month and refill if necessary with deionized or distilled water.

After each full electric recharge: acid fluid volume that increases during the charge will be kept safe within the battery capacity (no fluid overflow).

Why using a specific water? Tap water has ions and minerals that introduce contaminants and should not be used to fill batteries. Haulotte experts recommended using deionized or distilled water, that can be found and purchased as any other spare part. Caution: to refill batteries you must wear personal protective equipment.

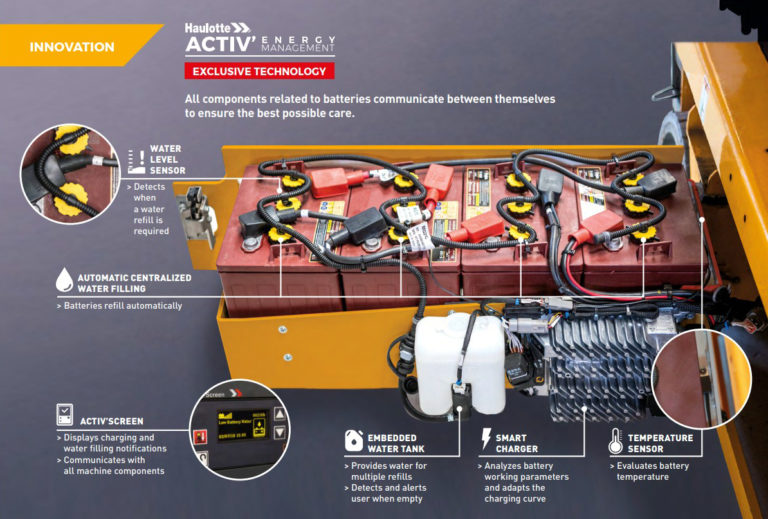

Haulotte innovation taking care of your batteries

To alleviate issues with batteries, Haulotte has developed Activ’Energy Management (AEM). This innovation optimizes the performance and lifespan of batteries by combining a smart charger with water refilling solutions to significantly reduce the battery maintenance and replacement costs.

The smart charger respects all the battery charging parameters. It also integrates many specific programs dedicated to battery maintenance such as an equalizing program and a desulfation program.

The best way to anticipate and solve battery maintenance problems is to combine Haulotte’s Sherpal telematics solution with AEM Technology. Sherpal helps communicate, diagnose, and monitor every battery fault codes.