The third line of the Toulouse metro, scheduled to open in 2029, is one of the most ambitious urban projects currently underway in France. With 27 km of tunnels and 21 stations to be built, this exceptional project involves specialized teams from around the world and logistics of rare complexity. Alongside these international experts, Kiloutou is playing a major role in providing reliable equipment that is perfectly suited to the extreme conditions underground.

To understand the technical and human challenges of this collaboration, we met with Nicolas Guilbaud, Regional Sales Director for Occitanie and project manager for Kiloutou.

Working with underground experts

The Toulouse metro attracts underground specialists who are accustomed to major international projects: railway tunnels, metros in Sydney, complex infrastructure in Europe.

Their standards are very high, and they are the ones who technically define the equipment required. Kiloutou’s choices are therefore guided by these professionals, who validate each machine according to specific constraints: working height, traction, permissible weight for crane descents into stations, turning radius, ground stability, etc.

Nicolas Guilbaud confirms: « Our customers are true experts. They are the ones who know their constraints perfectly and dictate their needs. We never choose a model at random. »

It is in this demanding context that a Haulotte aerial platform, the HA120PX, has been chosen for several key operations.

Organizing to meet the scale of the project

At the very start of the project, Kiloutou implemented a unique operating procedure designed to absorb the volume and diversity of requests. The project is structured into seven lots, each monitored by a dedicated sales representative from Kiloutou. This approach allows for constant monitoring, a smooth flow of information, and perfect coordination between the technical, transport, and administrative departments.

« Without a dedicated organization, we would have quickly been overwhelmed. We had to create our own project mode to remain efficient and consistent, » explains Nicolas Guilbaud.

This meticulous internal work ensures that the companies working on the site have the right equipment at the exact moment they need it.

Very different uses above ground and underground

Supporting the construction of the viaduct

Above ground, some sections of the metro are built on a viaduct with pillars reaching nearly ten meters in height. The teams use articulated aerial work platforms, including Haulotte models, to guide the installation machines and adjust the prefabricated elements. The precision of the movements, the repetition of the operations, and the height constraints make these platforms an indispensable tool for the smooth progress of the project.

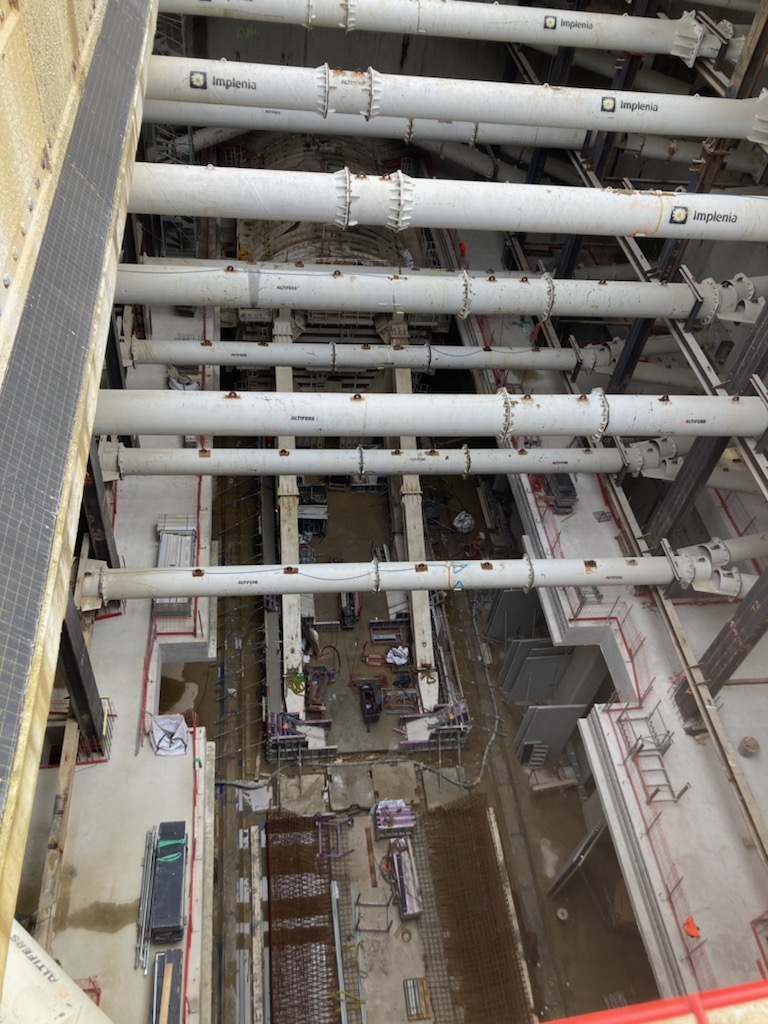

Working in an extreme environment: underground

Underground, the setting changes completely. The 120-meter tunnel, a veritable mobile factory, advances by digging, laying rings, and gradually shaping the future subway tunnel. Around it, operators must make adjustments to the waterproofing, install support structures such as struts, or work in the future stations that are being excavated. The ground is muddy, uneven, and sometimes unstable. Access is limited and visibility is reduced.

For Nicolas Guilbaud, « the underground is a turbulent environment. You need a machine that is reliable, maneuverable, and above all, adapted to ground conditions that can change from one day to the next. «

The HA120PX perfectly meets these needs: four-wheel drive traction, precise articulated arm, proven stability. Its working height covers exactly the most frequent needs of the teams (approximately six to seven meters), without oversizing the operations.

Why the Haulotte HA120PX was the obvious choice

The HA120PX has proven to be an excellent compromise for the Toulouse metro. The machine combines power, agility, and reliability, three decisive advantages in such a demanding environment.

« When we deliver a Haulotte aerial work platform, we know that the equipment will do the job. On such a challenging site, having confidence in the machine is essential, » says Nicolas Guilbaud.

Before each delivery, Kiloutou sends the technical data sheets to customers for approval: every detail counts, especially the weight of the machine and its ability to operate on complex terrain, such as a metro station under construction.

Reliability, safety, and equipment protection

One of the main challenges of underground work is the durability of machines that are constantly exposed to mud, moisture, and concrete splashes. These conditions can eventually affect certain sensitive components, particularly control boxes.

As Nicolas Guilbaud points out, « a machine can remain underground for six months. When it comes back up, it has inevitably been through a lot… Appropriate protection would clearly extend the life of sensitive components. »

On this type of site, the reliability of equipment is not limited to its mechanical performance. It also involves protecting critical areas to limit premature wear and unplanned interventions.

To meet these constraints, Haulotte already offers options designed for demanding environments, such as the Hostile Environment Kit. Designed for dusty, muddy, or wet construction sites, this type of solution aims to protect key machine components, particularly controls and exposed parts, while maintaining a high level of performance and safety.

This approach is fully in line with the logic expressed by users in the field: anticipating extreme conditions to extend the service life of equipment and ensure its safe operation over the long term.

Despite these extreme conditions, field feedback on the HA120PX remains extremely positive. Operators, who are often highly experienced, appreciate its precision and stability, and Kiloutou teams have noted its reassuring level of reliability.

The Toulouse metro construction site demonstrates how reliable and perfectly adapted lifting equipment can contribute to the success of a major urban project. Thanks to the robustness of the Haulotte and the rigorous organization put in place by Kiloutou, the underground teams have tools capable of supporting the progress of the tunnel boring machine and the construction of stations in extreme conditions.