Mobile elevating work platforms (MEWPs) are one of the safest ways to work at height. However, operators must remain vigilant regarding their external environment, especially when working near power lines, to avoid electrical risks. Here is some advice to reduce the chance for electrocution.

All about electrical risks

Electrocution is one of the leading hazards with the use of aerial work platforms. It is often due to:

- Lack of awareness of the proximity of overhead power lines

- Complacency of the voltage running through the cables

- Accidental contact of equipment with overhead power line

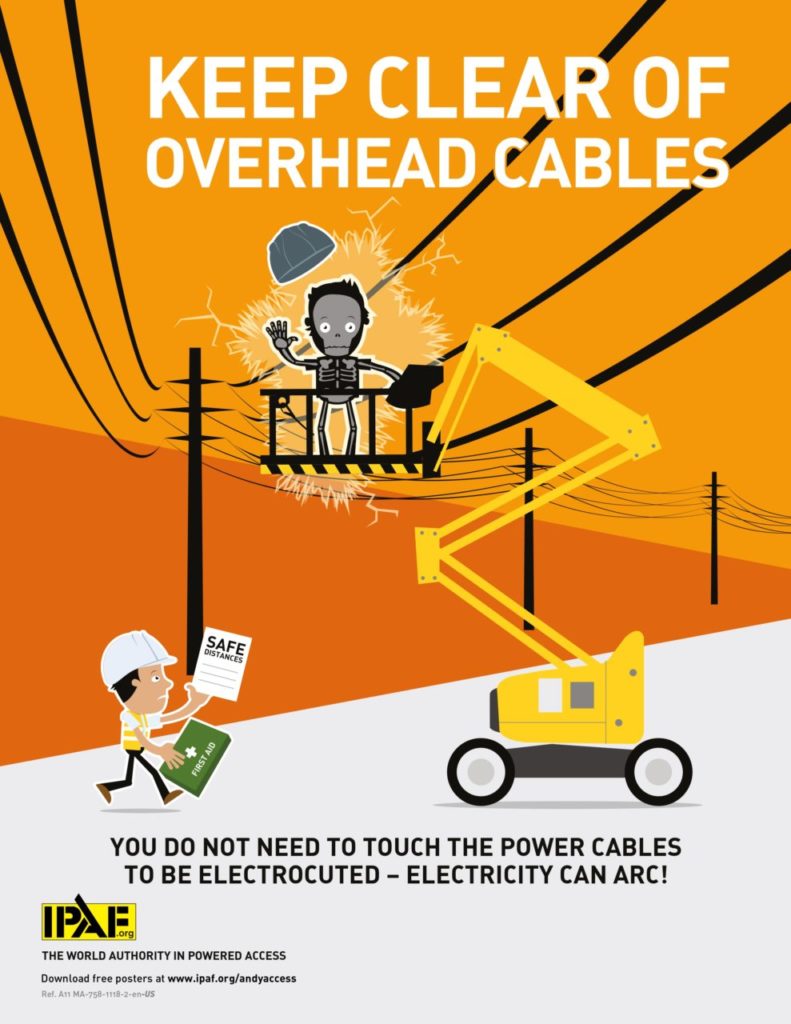

Remember, electricity can arc! You do not need to touch the power cables to be electrocuted. Arc flashes are sudden bursts of energy through the air due to a high-voltage gap between two surfaces. They can also be caused by equipment failure, dust, or corrosion. Intense heat can seriously burn the workers nearby.

Overhead power line guidance

Always keep a safety gap between you, your equipment and the power line. Before work can begin, contact the utility operator to determine if the energy source can be de-energized. If ‘de-energizing’ is not possible, do not go nearer than the minimum approach distance (MAD) recommended by the International Powered Access Federation (IPAF).

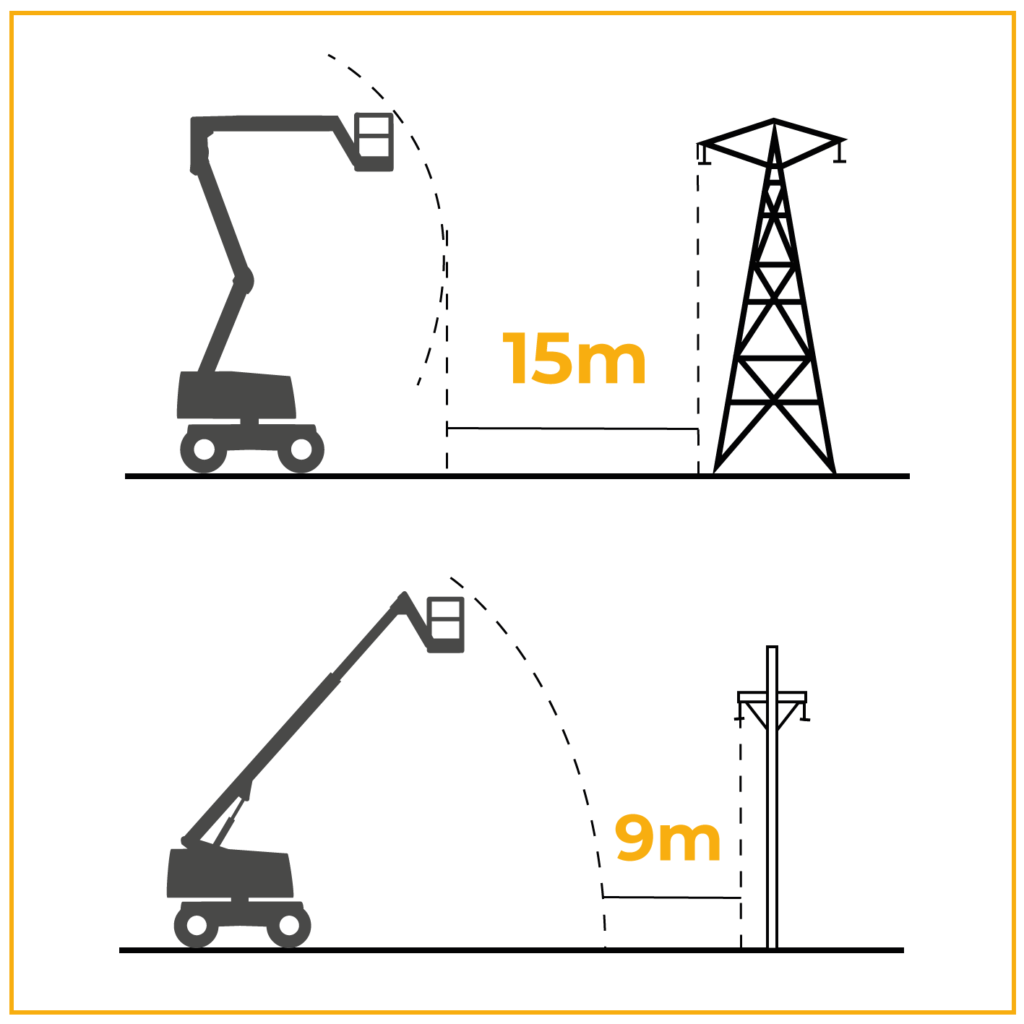

According to the IPAF, the safest distance to approach ‘live’ overhead cables when a boom is fully extended is:

- 15 meters (50 ft) from electrical pylon

- 9 meters (30 ft) from cables on wooden poles

Should the operator need to work any closer to power lines, seek expert advice (contact the power supplier) and ask for extra supervision.

Electrocutions can be prevented through proper planning, risk assessment, site management and continuous observation by the operator of potential electrical hazards. Make sure an emergency plan is in place for a prompt rescue; timing can make a very significant difference to the injuries sustained.