The Australian Legislation requires a major inspection of all MEWPs after 10 years of service. In this article find key information about this inspection and how you can turn this obligation into an opportunity for the safety of your teams!

An Australian regulation:

The Australian Standards of Safety, (specifically AS25)* provide for a Major Inspection for all EWPs after 10 years of service and every 5 years thereafter. This includes the dismantling and thorough examination of the machines, needing the skills of experienced technicians. If the decennial control is not performed and an accident occurs, the owner of the machine is responsible for the damage.

What are the tangible benefits of such an inspection?

By passing the ten-year inspection, you:

- Benefit from a safe and reliable aerial work platform: your machine is fully operational, ready for use and compliant with the existing regulations.

- Enhance your machines’ lifespan significantly: you just have to carry out regular preventive maintenance after the inspection to maintain optimum performance over many years.

- Reduce your financial risk: not only do you improve the residual value of your asset, but the inspection is amortized five times faster than if you had purchased a new platform.

Does my MEWP need a 10-years inspection?

Any EWP (Elevated Work Platform), greater than 10 years old needs to have a major inspection including the dismantling and thorough examination of the machines.

How much does it cost?

The cost of an inspection depends on the type of MEWP, generally it can be considered that the inspection cost is 15-22% of the purchase price of the machine.

What is involved in an inspection?

It is always beneficial to use the manufacturer to complete a 10 years inspection because they have better knowledge of the machine’s specifications, even the oldest. Using the manufacturers’ recommendations and various R&D files at their disposal, they live evaluate the condition of the platforms with absolute precision. Thanks to their experience, machine downtime is reduced to a minimum.

For example, Haulotte 10-years inspection is conducted in 3 stages:

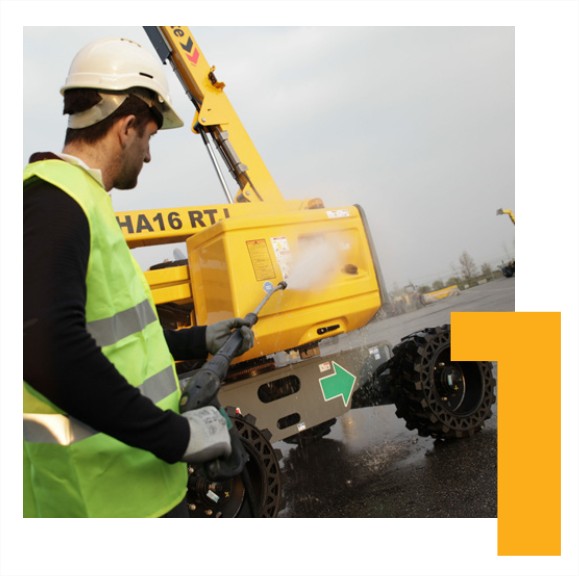

The machine is washed, and a full function test is performed, a visual inspection is made and a report on any abnormalities is written. Technical teams ensure that there are no leaks in the cylinder seals or counterbalance valves and test pressures.

The machine is dismantled, and all internal components are stripped to allow a complete and thorough inspection. Crack tests and magnetic particle tests, checks of all critical components are performed to detect signs of fatigue. All components are inspected, tested, cleaned, lubricated… The tolerance of all wear components is tested. Components are refurbished, systems repaired and upgraded if necessary.

Only original spare parts are used to ensure optimum safety.

Components that are heavily rusted are sandblasted and prepared for painting.

Once all components are cleaned and repaired, assembly begins, and a full service is performed. New decals and a compliance plate ensure the machine meets the Australian standards. The machine undergoes several functional tests before leaving our workshops. Haulotte provide a certificate confirming the completion of the 10-years test with a checklist of the work done certifying the machine conforms to standard.

Discover a small part of the inspection process of an electric scissor:

What about other countries?

The 10-years inspection is an Australian particularity, each country has its own rules and specification, however as a manufacturer Haulotte recommends carrying out general inspection according to the regulations of the countries (every 6 months in France, vs. a maximum interval of 13 months in the United States according to the ANSI standards).

Get more information about general inspection on our full article: All you need to know about periodic general inspections

In all Haulotte subsidiaries, a large team of experts and field technicians will be able to answer your questions about preventive and curative maintenance of your machine.

Find the subsidiary nearest to you and contact them > Haulotte Network

*EWPA Code of Practice for Power-Operated Elevating Work Platforms 6.4.5 of AS 2550.10